Time,

like an ever-rolling stream keeps moving. Technology advances. Civilization brings more and more rules. Every tragedy from the Titanic to the Herald

of Free Enterprise to the recent sinking of the Costa Concordia demonstrates

one thing that does not change – human nature has its weaknesses. Technology, to an extent, can produce the best

of missiles but the man behind the launching mechanism retains the control and

continues to be relevant. Better

educated, exposed and aware, perhaps, but still vulnerable to human frailties. When organizations adopt the system approach,

they set in place an atmosphere of continual improvement.

“A

bad system will defeat a good person every time” – W. Edwards Deming. This reminds me of a quote from the Cain

Mutiny, which in essence says, “Navy is a master plan devised by the genius for

execution by idiots”. This master plan

is the system, which should be so created that there is no need to blame the

individual. Every time the system fails,

the management reviews and acts to work on the procedures that comprise the

system. Improve the system enabling

better protection of the individual.

It is

ironic that individuals who are assigned the designing and then implementing of

the system often consider it a burden – little realizing that the system

approach takes management away from asking, “Who” to asking, “How and Why”. This results in further development of the

system rather than blaming the individual who was simply working within the

system.

In

the maritime world, the P&I clubs may well be paying the insurance dues

only after an individual is blamed, but the ISM Code in contradiction does not

encourage the blame culture. Good

management personnel understand this. Both

the ISM Code and the process-based management system standard, ISO 9001, take

management away from the blame culture and require continual improvement of the

system.

Management,

which can connect the clauses 4, 5, 8 and 9 of the ISM Code will understand and

appreciate the fundamentals of the Code.

These members of management will reap dividends in terms of “cash in the

bank”. The term, “cash in the bank”,

coined by QMII over 25 years ago, implies fewer to no accidents, resulting in

greater customer satisfaction and an increase to the bottom line. In the maritime world, the difference between

a detention and a catastrophe really is the cost the company pays – the loss in

revenue, the cash in the bank lost. It

implies loss of life, which in bare terms costs the organization. Loss of a vessel can ruin the company.

If it

is as simple as the correct implementation of the process-based approach, then

why does management not get it? Is it

because the maritime industry is so drowned in day-to-day activities that it is

more concerned with avoiding being detained, somehow getting away from Port

State Control (PSC) scrutiny, to be unable to implement the ISM Code in the

real sense? Alternatively, is it that

the old-fashioned top management (after all, those who go into management are a

generation or two behind those who actually go to sea and operate the vessels)

are not fully exposed to the true meaning of the system approach?

This analysis

is not new. Justice Sheen investigating

the loss of the Herald of Free Enterprise found a “disease of sloppiness” and negligence

at every level of the corporate hierarchy. What did that mean? It meant the system was not working. In present-day man-made tragedies, we, too,

conclude the system is not working.

Shore

management and those at sea should already know the value of a correctly

implemented process-based management system (ISM Code in conjunction with ISO

9001:2008). The implementation of the Safety

Management System (SMS) to prevent detention is not acceptable. It should be one of the benefits of a good

system. Aligning the system to just meet auditor requirements or take measures

to prevent PSC actions is weakening the system. The system will do that, however, the system

should have a more honest, larger purpose where it welcomes nonconformities (NC)to enable management (both at sea and ashore) to fulfill their obligations

under the ISM Code (clause 9). Correction

of NCs, followed by Root Cause Analysis does not end the cycle.

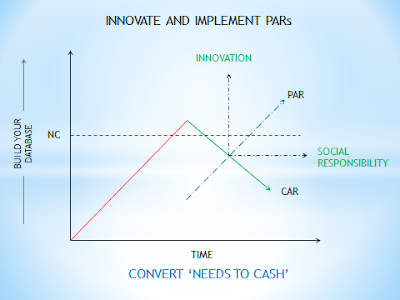

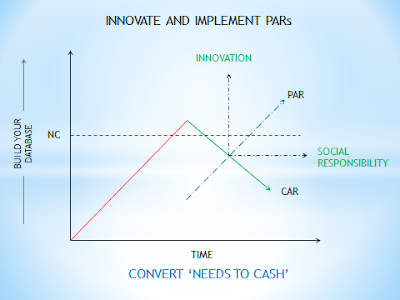

I

have drawn this graph above to show the benefits of respecting NCs (CARs). As

the data base builds information can be obtained from the data to objectively

analyze it and get the trends and predict potential NCs. When a system is first

implemented, the number of NCs will increase. This is because the system is now

recording the deficiencies. As the data base builds the analytical ability of

the system is able to get the desired information for the managements to

resource the system (be it in hardware, equipment, training or manpower) and

most importantly to recognize potential NCs. This then positively affects the

bottom line as now we are tackling potential NC and not being reactive to NCs.

There is a point in the system development of an organization where the NCs

drop and the PARs (Preventive Action Requests) increase indicative of the

employees having matured and embraced the system. This is the place where the

management also sees innovative ideas coming up and the management taking a

more socially responsible role.

Preventing

detention too often becomes the Master’s primary responsibility to the shore

based management. For PSC activities not

to reveal NCs is a daily short-term goal. Actually, this is counterproductive to the

expectation of the Code and the system approach in general. It encourages “hood winking” the PSC officers.

In my experience at sea and in my

interaction with seafarers I have come across incidents of seafarers being paid

‘bonuses’ to get a clean audit report. If management takes that path, true

safety cannot be achieved. The PSC

officers are stakeholders in maritime safety at sea. Why have the PSC officers come in? They meet a public outcry and demand following

the numerous tragedies over the years. They

detain vessels in order to prevent disaster at sea from occurring. What would the management prefer – a catastrophe

or a detention? Which is less expensive?

In

the selection of Top Management (TM) at sea, be it the Captain, the Chief

Engineer or the Hotel Captain (on passenger vessels from the Titanic to Costa Concordia)

– if the Master does not perform or does not conduct him-self professionally or

as per expectations, whose fault is it? Management ultimately picks the crews. The hiring procedure needs to be targeted. Those at sea are performing to the best of

their abilities and working hard; it is their profession and life. We must never forget that they are performing

as per the selection criteria that management has set! Often for seafarers the relationship with the

vessel is from ‘gangway to gangway’. How does a company go about ensuring that

its seafarers are equally invested in the success of the system? Some say that

retention of seafarers is the answer. But is a high retention percentage

indicative of a good ISM culture? The answer again lies in a better management

system. The Culture should filter top

down. The blaming of individuals should shift to blaming the system in order to

encourage a more open system. There

should be no fear in exposing NCs.

The

only bad nonconformity is the one we do not know about. A system should be created which welcomes nonconformities. A detention is a NC, which has saved an

organization from a likely catastrophe. Detentions

are expensive; therefore, the need to create an SMS in the true spirit so it

ensures NCs are detected internally, well in time, enabling management to take

corrective action to determine the root cause. To do that after each mishap, management

should not jump to the CHECK stage of the Plan-Do-Check-Act (PDCA) cycle.

They

should instead go back to the ACT stage and carry out better management reviews,

leading to better planning followed by correct implementation (DO) of the

system. The system approach, correctly

implemented, will lead to a system, which will work. Moreover, when the system works, one of the

many benefits will be few to no detentions. The ISM Code is the basis for such a system. An investment in a correctly designed system

and the implementation together with active participation by management will

ensure requirements are met. When

requirements are met, there will not be any detentions. Let us not prepare for audits,

detentions and PSC exams. That principle

is incorrect. Let management encourage

those at sea, and those who manage the vessels from shore, (as the

Superintendents, Port Captains, DPs and CSOs, etc.) to work together in the

interest of a system which functions and leads to safety at sea.

The

sinking of the Costa Concordia has brought into focus several SMS-related

failures, from which timely and correct lessons must be learned to prevent the

recurrence of similar catastrophic events.

These accidents will shape industry’s culture and motivate industry

stakeholders to make vessel operations safer in an effort to continue to

sustain the shipping business and ultimately create “cash in the bank”.

The

ISM Code recognizes that human error is the cause of the majority of

accidents. The Code requires delineating

responsibilities of the ship and shore side management, creating the system and

then addressing the coordination of the ship-to-shore support. If about eighty percent of marine incidents

are caused by human error, companies then have the responsibility to create true

organizational management systems, which help humans, prevent and mitigate such

incidents. The management system is

documented to the extent necessary for effective planning, prevention, operation

and control. The most important parts of

any management system are not documented as they involve leadership, care and

coordination.

The fish-bone diagram above indicates the principled working of a system. The inputs are worked on using the system to produce the desired output. The passengers coming

on board will need the entire work spectrum indicated in the fish-bone diagram

to work together under the Top Management exercising care and coordination for

the output to be positive. For the satisfied passengers, to continue to

patronize the company because, their expectations have been met in terms of the

holiday, safety, and security and pollution prevention.

The fish bone diagram above has the vital rib – Care and Coordination – implying active

and constant participation of the top management. The PDCA cycle at the Act

stage (please see diagram above) requires the TM to act based on the review of

the system. Audits are not meant to deliver changes or improve the system. If

audits and auditors could improve a system, then auditors would be the CEOs of

the shipping companies! It is the management that improves their systems. For this,

they must understand their systems and lead the implementation of the system by

example. To do this, management must

admit they also need to be trained.

The

correct implementation of the SMS, based on the ISM Code, will ensure that

ships operate safely. The Code addresses

the key provisions such as SMS objectives, safety and environmental protection policy,

company responsibility and authority, designated person, master’s responsibility

and authority, resources and personnel, shipboard operations, emergency preparedness,

reports and analysis of nonconformities, accidents and hazardous occurrences, maintenance

of the ship and equipment, documentation, company verification, and review and

evaluation. All of the provisions of the

Code are designed to work interactively and in harmony with each other to

enable the management system to be effective.

However, none of this can deliver the desired results without the total

involvement and commitment of the company’s top management. Blaming individuals

will only correct one person and not the system. To improve the system, the root cause should

be considered. The management must take

the blame for having a poor hiring process and lead the change by re-designing that

process. When the Captain at sea fails

in his role, management must read it as the process having failed, not having

been designed correctly. It requires

going back to the PLAN stage of the PDCA cycle.

One

of the main risks that any shipping company encounters is the potential

disconnect that can occur when the procedures in the SMS are not being followed

by shore side personnel, seagoing officers and crew. The worst that can happen to a company is

when those ashore believe that the procedures are being followed, when in

actuality, due to, for example, over documentation or lack of awareness and

training, they are not. Seafarers in our

courses share experiences of over-documentation in certain companies where the

‘paper’ eventually takes more importance that the actual procedure. This

disconnect again is indicative of a system not functioning. It is indicative of a cookie cutter system

based on generic templates (a common culture in the maritime industry). The designing of a system must be based on the

“As-Is” or current state. If consultants

are used to assist in designing the system, beware of those who promise to do

it cheaply sitting in their offices and providing master solutions! If you accept these, then as TM you have

already sown the seed of a weed. Do not

expect it to give you roses! Good

investment at the PLAN stage of the PDCA cycle is vital, in terms of both money

and time. Investment in designing the

correct system based on the existing state is vital to the success of the

system.

Any

major marine incident investigation, like the Costa Concordia, should focus on

the ability of a company to effectively implement their SMS procedures and

whether or not there were any gaps in how the SMS procedures were applied.

If a

company believes it has a perfect system and rests on its laurels, it is doomed

to failure.